Internal Live Chat FAQ

All Files must be 300 DPI or a Vector File. Preferred file types are .PSD, .TIF, .EPS, .AI, .PDF, and .JPG. Design should be sized to print. See File Prep for more info on how to prepare your order. Orders cannot be started until we have usable artwork.

Free for all basic orders! Any orders with printed or heat pressed custom tags will require setup fees, see the apparel finishings page for more info.

Red Eye Media's standard turnaround time is 3-5 days after artwork approval. If you have a specific in hands date, please let us know so that we can make sure to make it happen.

Yes. Different shirt styles and brands are ok as long as the ink colors remain the same. You must order at least 12 of each shirt style, you can mix and match sizes within each style.

You can order as many different shirt sizes as you want and you DON'T have to order in dozens, unless otherwise stated. Certain brands require ordering in half dozens.

Of course! We print on hundreds of different brands but to make it easy we only list the most popular ones. As long as we can get the blanks we will print it for you. Just drop us an email and we will see what we can do!

Yes. Your payment must be received before your order is printed.

Maybe. Why don't you drop us an email and we'll see what we can do!

Discharge printing is the process of bleaching the dye out of the shirt, leaving its natural color showing through (usually a tan color). We can also PMS match discharge ink, however results vary depending on shirt color & brand. The only major downside is that with discharge printing you must wash the shirts before they take their "no feel" state. We have been working with discharge inks for over 5 years now.

Waterbase printing is very similar to discharge printing but for white and light colored shirts. The inks are dyed into the fabric. When used on dark color fabrics it gives a strong faded/vintage look. Keep in mind that when using light ink colors on dark shirts the ink colors will be tinted by the shirt color. For example white inks on a black shirt will cause the inks to be a light grey. Waterbase inks must be washed before they take their "no feel" state.

This is the traditional style of printing. Inks are thicker and rougher than our standard printing, and the ink sits on top of the shirt. These inks can be printed on any garment or fabric and work best in small print areas. Plastisol inks will be used on all 50/50 tees in place of our Standard inks.

This is the process that you will want to use when you have a full color design or a photograph. We can do both full color process and simulated process. Every design is different so its best that you show your sales rep the artwork and they can tell you the best way to print it. Due to the difficulty involved there is a 1 time setup fee to get your artwork ready for printing.

Foil is a great option to really make your shirts pop! Sheets of foil are heat pressed on top of plastisol inks. We can also mix foil with standard printing but waterbase inks must be used for the other colors being used. Keep in mind that foil does not last as long as normal printing and can start to peel after only a few washes if shirts are not taken care of. To extend the life of the foil please wash these garments inside out in cold water then hang dry. We print a similar color of ink under the foil to help make the shirts last longer when they do start to peel.

Not every color garment discharges well. We did some testing to find out what colors worked and what colors didn’t when using discharge inks. Due to the intensity/amount of the dye used to make the shirts bright and vibrant, the following shirts do not work well when using discharge ink (which includes our Premium Standard Ink): Kelly Green, Red, Royal Blue, Lapis, Cobalt, Purple, Forest, Teal, and Turquoise. If you are going to print on these shirt colors, please note that lighter colors like white and yellow will be influenced by the shirt color remaining underneath.

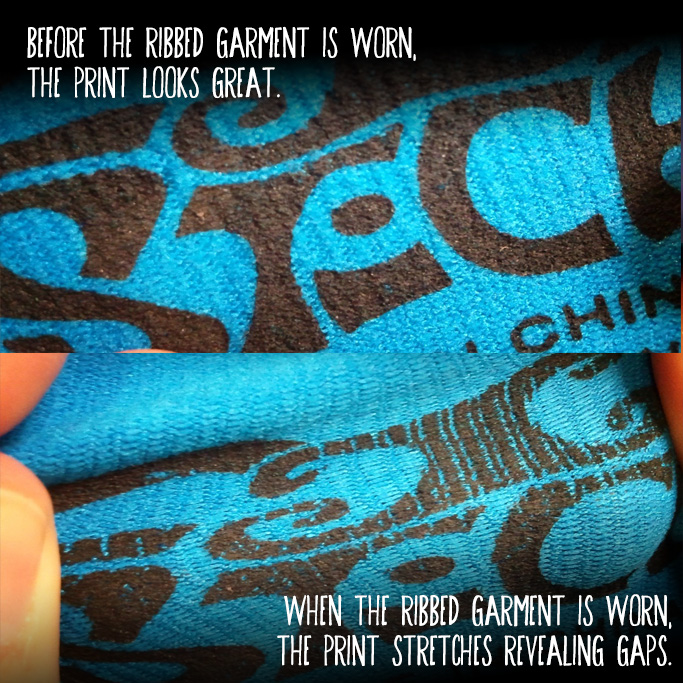

Ribbed garments provide the best form fit of all blank shirts as they stretch to meet the size of the individual wearing them. This is great the for final consumer but makes printing on them a challenge. When you pull a ribbed garment onto the press, it is not stretched out, so the ink only goes on the top of the ribs. Then, when the shirt is put on, the ink pulls apart, exposing a gap between the ribs that is not printed. We can apply more pressure on the press to try to force the ink into the gaps, but this limits the amount of detail that is actually shown on the garment. Because of these issues, we strongly suggest that if you want to print on ribbed garments, consider the use of discharge inks and or waterbase inks for lighter colors. Here is an example:

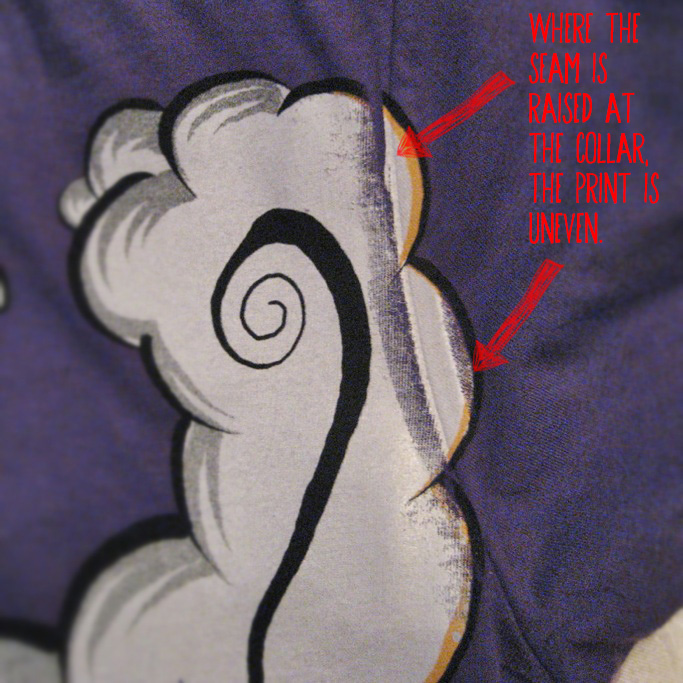

To get the best quality print when screen printing, we need as flat of a surface as possible between the pallet (that the garment lays on) and the screen (that holds your design). The fronts and backs of t-shirts are consistently smooth and the same thickness, which allows us to get a perfect print every time. However, when you print over a seam, pocket or zipper, it creates an inconsistency, because these are thicker portions of the garment. When you print over these portions of the garments, it creates a gap in the print where the ink from the screen does not touch the shirt due to the ridge caused by the seam. Here is an example:

Jumbo prints account for approximately 50% of all orders placed at our shop. People want as big of a print as possible. With standard unisex or mens tees, this is typically not a problem. However, some shirts have issues when printing Jumbo:

- Tank Tops: Most tank tops are low cut at both the neckline and the sleeves. Printing jumbo prints on these garments can cause print defects from printing over the seams.

- V-Necks: The neck line of the v-neck may cut into the design. Please take this into account when you are designing your shirt.

- Girls Tees: Jumbo pallets are wider than most girls tees. In order to get the girls tee onto the press, it has to be stretched. This can cause several issues: possible ripped shirts, loss of form from stretching past normal means, a distorted image due to stretching the shirt, and the design being cut off the bottom/sides of the shirt.

With advancements in screen printing (including high mesh count screens and specialty presses) we can recreate a level of detail with t-shirts that was previously unattainable just 5-10 years ago. However, due to the way some garments are constructed, they will not work well with detail. The following is a list of those garments:

- Ribbed Garments

- Canvas Material (Aprons, Bags, etc.)

- Burnout Tees

- Pique Polos

These items do not work well with detail because they are not smooth like standard t-shirts.

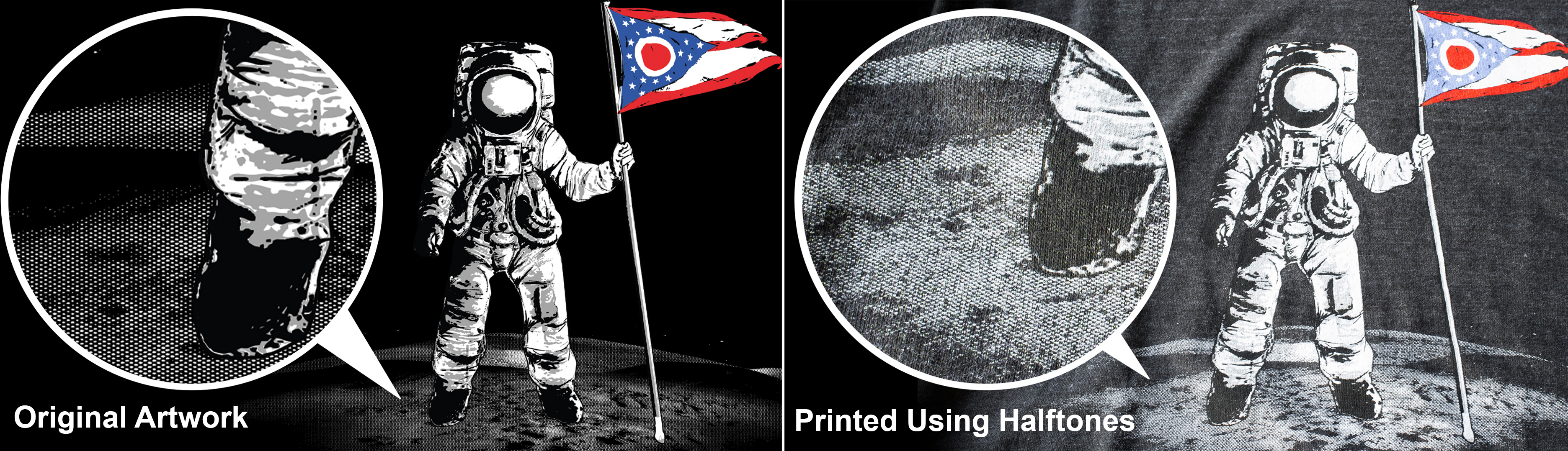

Halftones are small dots blended in a printed design that vary in size and space to create the effect of smooth, full-color imagery. If your artwork contains gradients or complex detail (such as a photograph), halftones are a great solution.

When printing tri-blends we always recommend using either 100% waterbase ink or a waterbase discharge ink to get the softest print possible. If you don't use waterbase ink, your only real option is plasitsol ink. We recommend that you only opt for a tri-blend tee if you are looking for a soft shirt with a soft print. Please note that without an underbase, tri-blend tees will have a faded/vintage look, which is what the shirts were intended for.

It is recommended that you leave at least 1" of space between the edge of your design and any shirt seams.

Rush jobs are completed in less than 48 hours after the final artwork approval. A rush job can be subject to a 30% addition of the total order.

Down below are our rush job upcharge for screenprinting:

- Rush Charges of 40% (2 business days)

- Rush Charges of 50% (24 Hours, after artwork approval)

- Rush Charges of 100% (Same business day, order & artwork needs to be in before 10am)

*NOTE TO AGENT: Most of the time we will waive this charge, we just need to let the customer know the overall cost and then we can use this as leverage to earn their business.

We accept company checks, cash, personal checks, Visa, Mastercard, Discover and American Express. We also work with PO's

Screenprinting is based on a few factors:

• Number of garments being printed is by far the most important criteria

• Number of colors

• Number of locations on the shirt

• Number of screens required to print the garment

Knowing the above will allow us to provide you with a better estimate.

We can provide you with an exact cost, what's the best phone number to call you?

Yes. However, quite often we can save you money by purchasing the product for you because of our volume discount with several vendors.

If you would like to bring your own garment, we have to first do a test sample on the fabric to make sure we use the correct inks and additives so that the impression can last for years to come. Not using the correct formula often can cause the ink to migrate (bleed) through the color of the garment.

Log In is required for submitting new FAQ. Click Here